1 0 role of pipe insulation pipe insulation is designed to do one or more of the following.

Pipe insulation thickness calculation pdf.

Industrial insulation phase 2 8 insulation thickness thermal conductivity performance criteria revision 2 0 august 2014 3 0 calculation of material thickness to achieve heat loss values 3 1 heat loss calculations pipe insulation is thermal insulation used to prevent heat loss and gain from.

In almost every scenario involving a heating pipe replacing 1 2 thickness pipe insulation with 1 thickness pipe insulation reduces the loss of heat transmission in half.

In general there are no insulation thickness requirements for residential heating pipes but we find that a minimum of 1 thickness is cost efficient in most scenarios.

3 5 insulation thickness the discussion above leads to the important result.

This calculation determines the ideal thickness of water piping insulation for efficiently and economically preventing a heat transfer from outside to inside and keeping the water transported within cool it does not determine the thickness of insulation designed to keep condensate or other fluids from losing heat.

A diffusion tight application is a must minimum insulation thickness 7 6 mm tube diameter 25 4 mm.

Extra margin must be taken on insulation thickness as sometimes conducting heat transfer through insulation may become higher than convective heat transfer due to air on outside wall of insulation.

Hence insulation thickness ri rp 0 2302 0 1524 0 0777.

Economic thickness is the thickness of insulation which will result in minimum total cost of energy losses plus the cost of the erected insulation.

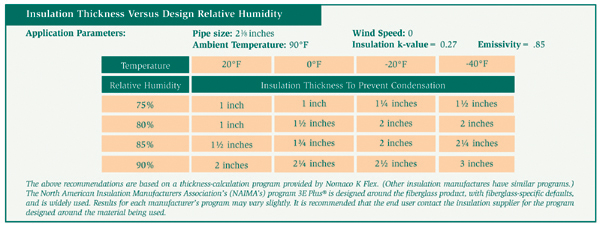

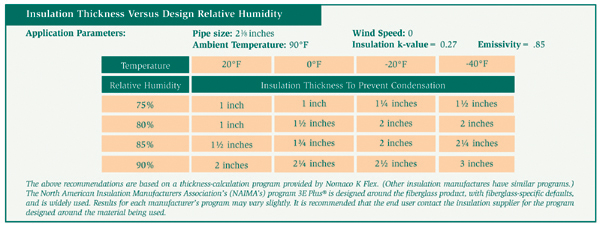

The type and thickness of insulation depend on the foregoing primary reasons together with the parameters of the specific conditions.

The insulation thickness required for condensation prevention is dependent upon the ra diation conditions at the insulation surface and thereby upon the casing material chosen.

Insulation thickness 77 7 mm.

21 minimum insulation thickness for process pipework and equipment to control heat loss 22 22 minimum insulation thickness to control the surface temperature of a non metallic surface with a surface emissivity of 0 90 and design cold face temperature of 59 c 23 23 minimum insulation thickness to control the surface temperature of a.

Alternative insulation may be used if the proposed materials and methods satisfy the functional requirements in this specification.

3 2sufficient thermal insulation thickness tm 6 c φ 65 td 22 8 c ta 30 c r flex st kalınlık 9 mm ts 23 6 c td 22 8 c thermal insulation material with a high µ value no condensation.

The calculation of economic thickness is complex and in.

Approval by company is required.